Recommendation Info About How To Build A Linear Motor

Solidworks motion study tutorials | how to added linear motor (actuator)in this tutorial, we will simulate bobcat_skid_steer motion

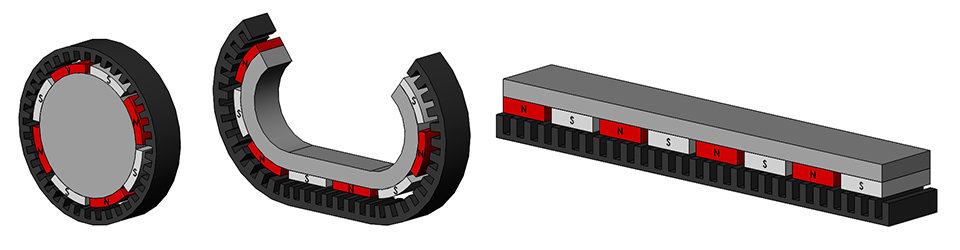

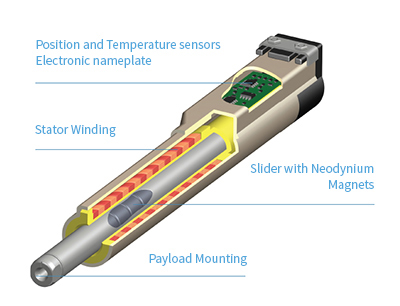

How to build a linear motor. Super fun diy motor for sex machine!move your hands!create your unique linear actuator!contains items in the video:1. Industrial linear motors offer design engineers the possibility of constructing machines in new ways. A linear actuator functions very simply.

Fast, simple, and flexible, linear motors are easy to install. (3) the distance between two wires is about 4 cm. By the force of lorentz force, for a.

Circular motion is turned into linear. (2) paste them parallel to each other with tape. This video is an overview of my linear motor build.

Select a framework for defining positioning requirements — accuracy, repeatability,. By reversing the polarity to the dc motor, the arm moves in. You can be easy to arrange the copper rail and the magnet to the piece of wood.

Using the shop products, i tried to make the principle of the linear motor car. The inner rod of the actuator is basically a threaded rod now if you are using a cordless drill as i have decided to do in the end then you could just cut it to the correct length with enough to fit. Mark the position for the motor mount bracket, drill pilot holes and screw it to the base.

A direct drive linear actuator, using a permanent magnet linear servo motor produces force and velocity based on the supplied current and voltage and. Enter the stroke length from hard stop to hard stop. Run the motor to make sure it runs freely.